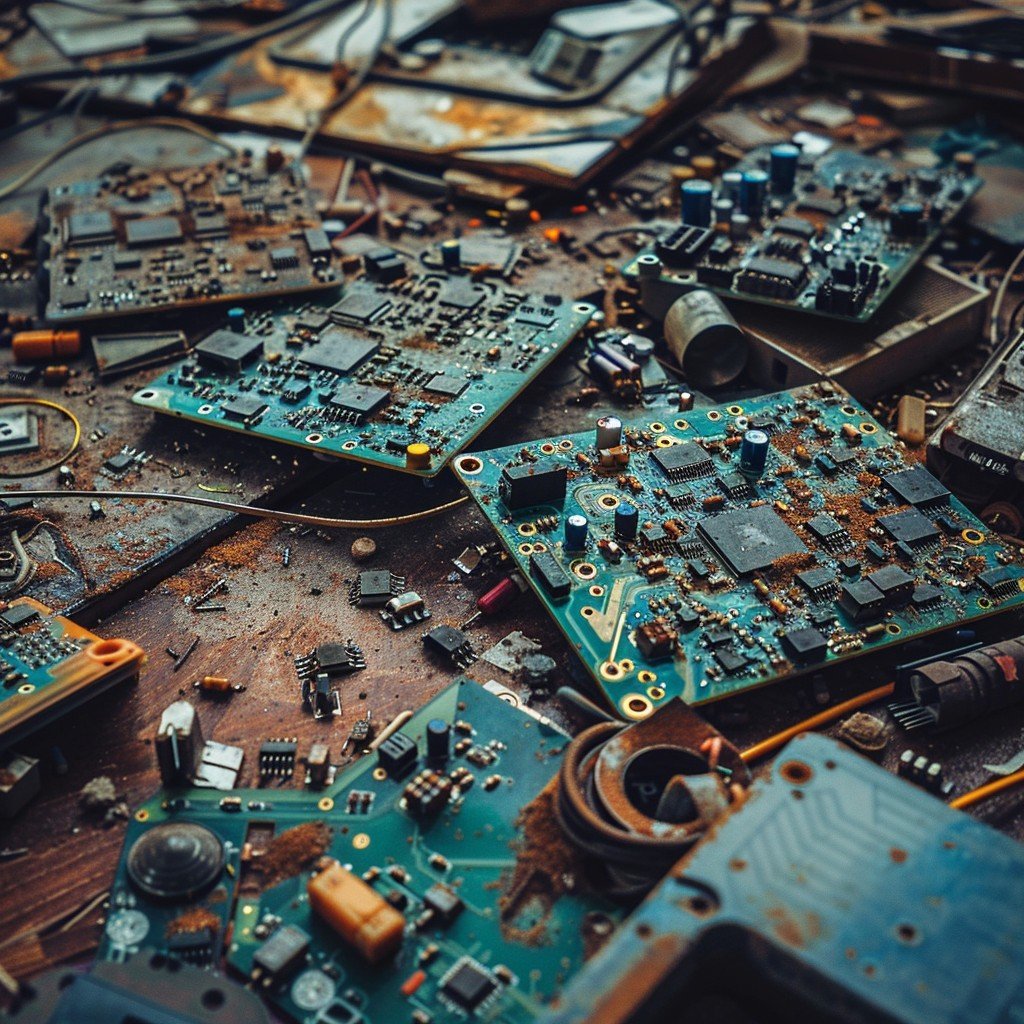

Technology is routinely designed and used in ways that create unnecessary waste. Devices are discarded early because they are fragile, difficult to repair, or uneconomic to support. Replacement is often cheaper than maintenance, and responsibility frequently ends at the point of sale.

This leads to short product lifecycles, avoidable material waste, and the loss of value in products that could otherwise remain useful for much longer. It also shifts environmental and social costs away from manufacturers and towards consumers, waste systems, and the environment.

We build initiatives to address these structural problems directly. Each one focuses on a specific point in the lifecycle, such as extending product life, supporting repair rather than replacement, reducing material impact, or improving end of life handling. The aim is not to optimise one metric in isolation, but to reduce waste and improve performance across the system in ways that are commercially viable and operationally practical.

The issues described above are not abstract. They are created by specific design decisions, commercial incentives, and missing systems. They persist because the default ways of building, selling, and supporting technology make waste easier than longevity.

Our response is to intervene at those points deliberately. We design initiatives that change how a product is built, how it is supported, or how its materials and end of life are handled. In some cases that means extending usable life. In others it means making repair viable again, reducing material impact at source, or improving what happens when a product is no longer usable.

Each initiative is therefore designed as a practical response to a defined problem, not as a general statement or a piece of branding. They are built to operate within real supply chains, real commercial constraints, and real user behaviour, because only interventions that work under those conditions can make a lasting difference.

The issue

Screen damage is one of the most common reasons mobile devices are replaced before the end of their functional life. A cracked or scratched screen often makes a device unpleasant to use, expensive to repair, or uneconomic to maintain relative to replacement.

This leads to large numbers of devices being discarded while the majority of their components are still functional, creating unnecessary material waste and embedded carbon loss.

Why it matters

Mobile phones are material and energy intensive products. Replacing a device because of superficial damage such as a broken screen results in the loss of the value embedded in the battery, electronics, casing, and manufacturing effort.

Reducing early replacement therefore has a disproportionate effect on waste reduction compared to marginal improvements in recycling or disposal.

How Ghost Coat addresses this

Ghost Coat is a ceramic screen protector combined with a screen replacement warranty. The protector reduces the likelihood of damage, while the warranty provides free screen replacement when damage does occur. Unlike disposable plastic screen protectors, it does not rely on consumable films and does not create additional plastic waste over the life of the device. It also avoids unnecessary packaging waste through the use of FSC certified packaging and compostable or recycled materials where packaging is required.

This structure is intentional. By removing the cost barrier to repair, the product makes repair the default response to damage rather than replacement of the entire device. It also shifts the economic incentive away from early disposal and towards keeping devices in service for longer.

Structurally, Ghost Coat functions as an insurtech product. The protection and the warranty are designed together so that risk, cost, and behaviour are aligned around extending device life rather than accelerating turnover.

How this differs from typical approaches

Most screen protection products focus primarily on appearance, short term durability, or aesthetic features. They are treated as disposable accessories and are rarely connected to repair or support systems.

Ghost Coat is designed as part of a broader lifecycle approach. It treats protection as a means to extend product life, reduce early disposal, and support repair rather than as an isolated consumer add on.

The issue

Premium technology accessories are typically made from virgin materials and designed for linear production and disposal. This is not because alternative materials or approaches are unavailable, but because the industry assumes that recycled inputs increase cost, reduce quality, limit scale, or complicate supply chains.

As a result, even high quality accessories continue to embed unnecessary material extraction and waste into products that are produced and sold at very large scale.

Why it matters

Accessories are replaced frequently and produced in high volumes. Even small differences in material choice and construction are therefore multiplied across millions of units, making this category a significant and largely unaddressed source of environmental impact.

At the same time, customers in the mid and high tier expect durability, finish, and experience to be uncompromised. Any approach that requires higher prices, lower margins, or a degraded product experience will not scale and will remain niche.

How The Rubbish Accessory Brand addresses this

The Rubbish Accessory Brand is designed to test and demonstrate that premium accessories can be made from recycled and responsibly sourced materials at the same price, the same margin, and the same scale as their conventional equivalents. It uses GRS certified materials, established manufacturing partners, and standard distribution channels in order to operate within normal commercial and operational constraints.

Products are designed to meet the same standards of durability, finish, and usability as other premium accessories. Sustainability is not positioned as an added feature or a trade off, but as an integrated design choice that does not alter the customer proposition or the commercial model.

How this differs from typical approaches

Most sustainable accessory offerings accept higher prices, lower margins, limited distribution, or reduced performance as the cost of using alternative materials. This keeps them niche and prevents them from replacing conventional products at scale.

The Rubbish Accessory Brand operates on the opposite assumption. It treats material choice and supply chain design as variables to be optimised within existing commercial realities, not as reasons to change the market positioning. The aim is not to create a separate sustainable category, but to remove unnecessary environmental impact from an existing premium one.

The issue

The issues described earlier extend beyond product durability and materials. Waste and value loss also occur in areas such as repair infrastructure, information and traceability, end of life handling, and material recovery. These parts of the system are often fragmented, underdeveloped, or economically misaligned.

As a result, even products designed with better materials or longer lifecycles can still end up being discarded prematurely or handled inefficiently at the end of their use.

Why it matters

If waste is shifted from one part of the lifecycle to another, or from one actor to another, overall impact is not reduced. Addressing only isolated parts of the system limits what can be achieved and risks creating unintended consequences elsewhere.

Long term improvement therefore requires interventions that consider the full lifecycle and the systems that support it, not only the physical products themselves.

What we are working on

We are developing additional initiatives that address these system level gaps. This includes work on improving repair access and information, better linking products to service and support over time, and improving how products and materials are handled at the end of their useful life.

This includes research into the reuse of reclaimed batteries from end of life electric vehicles, and the recovery of rare earth and critical materials from manufacturing and recycling waste streams such as black mass.

These areas are technically complex and still emerging. Our work focuses on understanding feasibility, material flows, commercial constraints, and where meaningful intervention is possible rather than on announcing products prematurely.

As these initiatives move from development into operation, they will be added here.

How this fits the overall approach

Each future initiative will be designed using the same principles and constraints as the current ones. They will be commercially grounded, operationally viable, and intended to function at scale within existing markets rather than alongside them.

Be the first to hear about our new initiatives and products